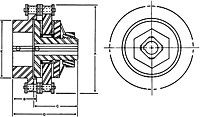

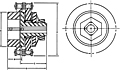

The Dalton OSDC (Overload Safety Device Coupling) provides overload protection through the use of an OSD unit combined with a roller chain coupling half counterbored to fit the OSD flange. Standard double-width roller chain is used to couple the basic OSD unit and the coupling half.

The OSDC can be set with a torque wrench for maximum load desired. The unit functions as a roller chain coupling until an overload occurs, causing the OSDC to disengage. The device is automatically re-engaged when the overload is eliminated.

FORMULA FOR TORQUE-HORSEPOWER (Foot Pounds)

TORQUE (Foot. Pounds) = (HPx5252)/RPM

HORSEPOWER = (Torque x RPM)/525

In furnishing a coupling half to be used in the "OSDC", care must be taken that a standard cut tooth sprocket is not used. The teeth of the "OSDC" coupling half are cut with a special tooth form to compensate for shaft misalignment.

Important Note:

The "OSDC" overload safety device can be made to suit your application. Send us your blueprints or specifications, for recommendations by our engineering department.

The OSDC can be set with a torque wrench for maximum load desired. The unit functions as a roller chain coupling until an overload occurs, causing the OSDC to disengage. The device is automatically re-engaged when the overload is eliminated.

FORMULA FOR TORQUE-HORSEPOWER (Foot Pounds)

TORQUE (Foot. Pounds) = (HPx5252)/RPM

HORSEPOWER = (Torque x RPM)/525

In furnishing a coupling half to be used in the "OSDC", care must be taken that a standard cut tooth sprocket is not used. The teeth of the "OSDC" coupling half are cut with a special tooth form to compensate for shaft misalignment.

Important Note:

The "OSDC" overload safety device can be made to suit your application. Send us your blueprints or specifications, for recommendations by our engineering department.